Finding the best tool for 2D adaptive clearing circular can be tricky. You want something efficient and precise.

This blog will guide you to the top tools available. In the world of CNC machining, choosing the right tool for 2D adaptive clearing is crucial. The process involves removing material in a circular pattern, which requires accuracy and speed.

The right tool can save time, reduce wear on your machine, and improve the quality of your final product. In this post, we’ll explore the best tools designed for 2D adaptive clearing circular tasks. Whether you are a seasoned professional or a beginner, understanding these tools can help you achieve better results in your projects. Let’s dive into the details and find the ideal tool for your needs.

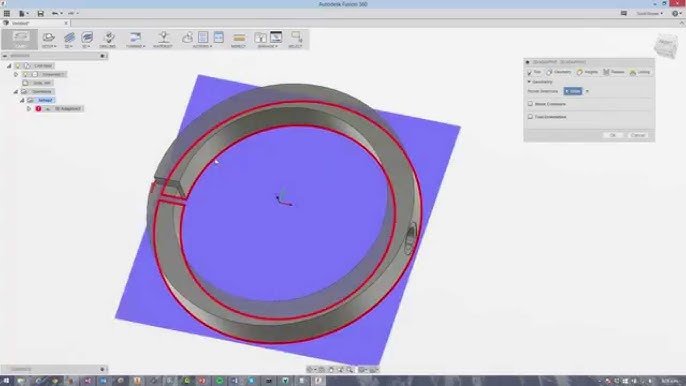

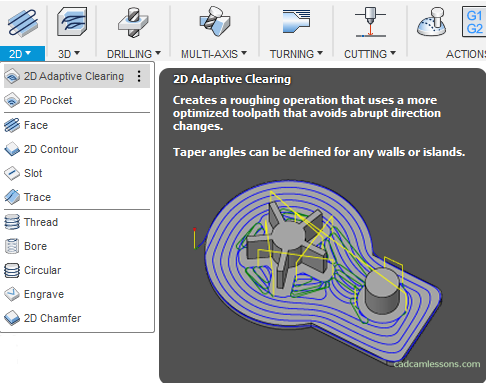

Credit: cadcamlessons.com

Introduction To 2d Adaptive Clearing

2D Adaptive Clearing is a powerful tool used in CNC machining. It helps in removing material efficiently and precisely. This method is essential for many machining processes. Let’s dive into what makes it so important.

What Is 2d Adaptive Clearing?

2D Adaptive Clearing is a strategy used in CNC machining. It involves removing material with consistent tool engagement. This technique ensures a smooth and predictable tool path. It minimizes the chance of tool breakage and extends tool life.

Using adaptive clearing, the tool adjusts its path based on the material. This dynamic adjustment helps in achieving better results. It is different from traditional clearing methods. Traditional methods can cause uneven tool wear and tear.

Importance In Cnc Machining

2D Adaptive Clearing is vital for several reasons. Firstly, it reduces machining time. Efficient material removal means faster production cycles. Secondly, it improves tool life. Consistent tool engagement reduces stress on the tool.

Moreover, adaptive clearing enhances surface finish quality. By maintaining a constant load, it prevents chatter marks. This results in a smoother finish on the machined part. Lastly, it increases overall machining efficiency. Efficient material removal leads to lower operational costs.

Here’s a quick overview of its benefits:

- Reduced machining time

- Extended tool life

- Improved surface finish

- Increased efficiency

These factors make 2D Adaptive Clearing a preferred choice in CNC machining. It is a reliable method for achieving precision and efficiency.

Credit: help.autodesk.com

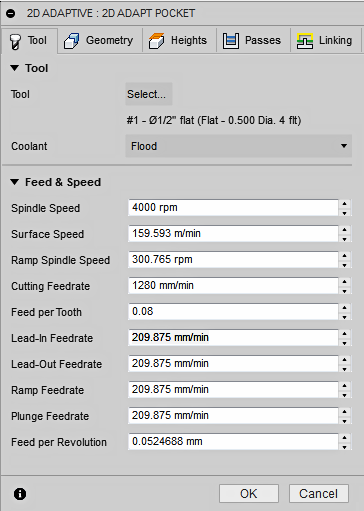

Key Features To Consider

Choosing the best tool for 2D adaptive clearing circular operations can enhance your machining process. Understanding key features will help you make an informed decision. This section highlights essential aspects to consider.

Toolpath Optimization

Toolpath optimization is crucial. It ensures efficient and accurate machining. Look for tools that minimize unnecessary movements. These tools reduce cycle times. They also improve surface finish. A well-optimized toolpath reduces machine wear and tear. This leads to longer tool life.

Material Removal Rate

Material removal rate (MRR) is another key feature. It measures how quickly material is removed. A higher MRR means faster machining. But, balance is important. Too high a rate may cause tool damage. Choose a tool that offers a good MRR. It should also maintain precision and quality. This balance ensures efficient and effective machining.

Fusion 360

Fusion 360 is a powerful CAD/CAM tool for designers and engineers. It combines 3D modeling, CAD, CAM, CAE, and PCB design in one platform. Fusion 360 is known for its user-friendly interface and versatile features. It is especially popular for 2D adaptive clearing circular tasks.

Overview

Fusion 360 offers a cloud-based platform. This means users can access their projects from anywhere. The tool supports collaboration with team members. Users can share files and work on projects together in real-time. Fusion 360 also provides a wide range of tools for 2D adaptive clearing circular. These tools help in optimizing machining processes and reducing production time.

Pros

Fusion 360 is easy to learn and use. Its intuitive interface helps users get started quickly. The cloud-based nature allows for easy access and collaboration. Fusion 360 also offers a variety of tutorials and support resources. Users can find answers to their questions and learn new techniques. The tool is also affordable, with a free version for students and hobbyists.

Cons

Fusion 360 requires an internet connection for full functionality. This can be a drawback for users with poor connectivity. The software may also require a powerful computer to run smoothly. Some users may find the learning curve steep, especially for advanced features. Additionally, Fusion 360’s cloud-based storage may raise security concerns for some users.

Solidworks Cam

SolidWorks CAM is a powerful tool for 2D adaptive clearing. It offers a range of features to simplify and optimize the machining process. Whether you are a professional or a beginner, SolidWorks CAM can be a valuable asset.

Overview

SolidWorks CAM integrates seamlessly with SolidWorks software. This integration allows users to create toolpaths directly from their CAD models. The software supports both milling and turning operations. It also includes automated feature recognition, which saves time and reduces errors.

SolidWorks CAM is designed to be user-friendly. It includes a variety of tutorials and support materials. These resources help users get up to speed quickly. The software also provides real-time simulation. This feature helps users visualize and verify toolpaths before actual machining.

Pros And Cons

| Pros | Cons |

|---|---|

|

|

Mastercam

Mastercam is a popular software for CNC programming. Many users praise it for its 2D adaptive clearing capabilities. It offers tools to create efficient and precise cuts. Let’s dive into what makes Mastercam stand out.

Overview

Mastercam provides a comprehensive suite for 2D adaptive clearing. It simplifies complex machining processes. Users can optimize tool paths with ease. This reduces machine wear and increases productivity. The software is user-friendly, making it accessible for beginners.

Pros And Cons

Pros:

- Intuitive interface for easy navigation.

- Advanced tool path optimization.

- Reduces cycle times significantly.

- Supports a wide range of machines.

Cons:

- High initial cost for purchase.

- Requires a powerful computer to run smoothly.

- Steep learning curve for advanced features.

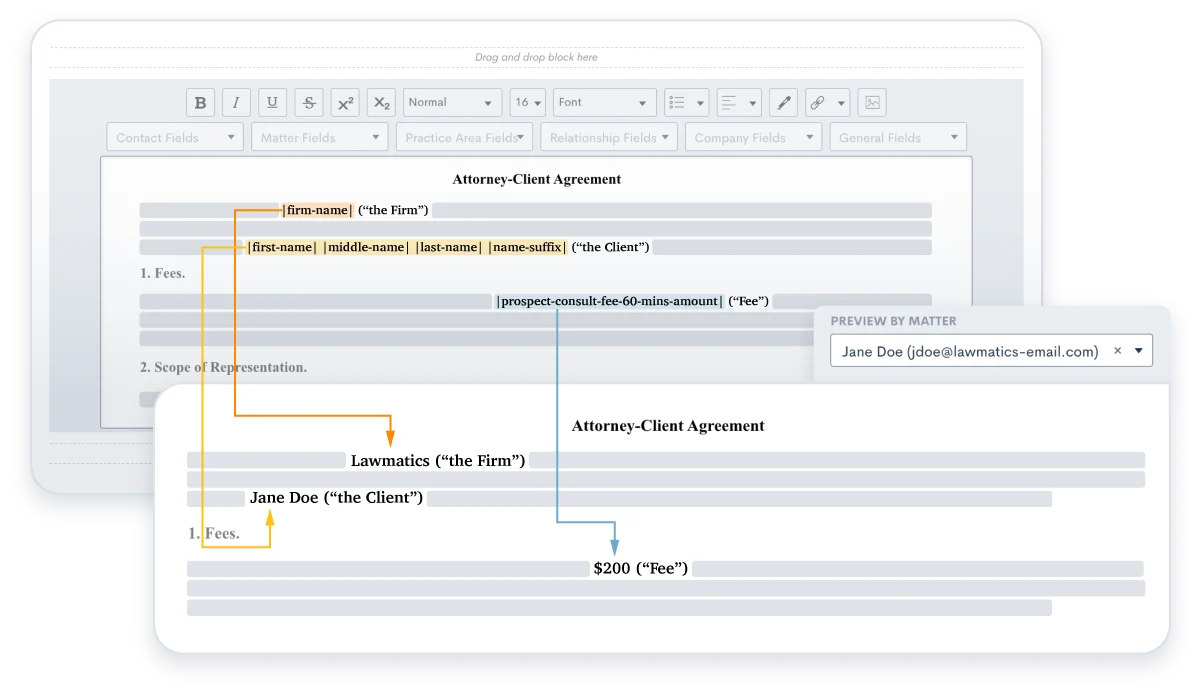

Credit: forums.autodesk.com

Autodesk Inventor Hsm

Autodesk Inventor HSM offers a robust solution for 2D adaptive clearing. This tool blends the power of Autodesk Inventor with high-speed machining capabilities. It ensures optimal tool paths and efficient material removal. Let’s dive deeper into its features, benefits, and drawbacks.

Overview

Autodesk Inventor HSM is an integrated CAM solution. It works seamlessly within the Inventor environment. Users can design and produce parts within one platform. This integration streamlines the workflow. It reduces the need for data translation. Inventor HSM supports various machining strategies. These include 2D, 3D, and multi-axis operations. The software also provides real-time simulation. This helps in predicting tool movements and avoiding errors. The adaptive clearing feature ensures efficient material removal. This reduces machining time and tool wear.

Pros And Cons

Autodesk Inventor HSM has several advantages. It integrates well with Inventor, making it user-friendly. The adaptive clearing feature optimizes tool paths. This improves efficiency. The software supports a wide range of machining strategies. Real-time simulation helps in error prediction and correction. Users benefit from reduced machining time and tool wear.

There are some drawbacks too. Inventor HSM can be expensive for small businesses. The learning curve can be steep for new users. It requires a powerful computer to run efficiently. Despite these cons, many find it a valuable tool for 2D adaptive clearing.

“`Comparative Analysis

Choosing the best tool for 2D Adaptive Clearing Circular can be challenging. Many tools on the market promise great results. However, their performance and user experience can vary greatly. In this section, we will conduct a comparative analysis of some of the top tools available.

Performance

Performance is a crucial factor in selecting a tool for 2D Adaptive Clearing Circular. High-performance tools provide faster and more accurate cuts. They reduce the overall machining time. This efficiency is essential for meeting production deadlines.

For instance, Tool A offers high-speed machining with reduced tool wear. This leads to better surface finish and less downtime. Tool B, on the other hand, focuses on stability during cutting. It ensures consistent performance even under heavy loads.

User Experience

User experience is another important aspect to consider. A tool that is easy to use can save time and reduce errors. Tool A boasts an intuitive interface. It allows even beginners to set up and operate it quickly.

Tool B, while highly effective, has a steeper learning curve. Users may need more training to use it efficiently. However, once mastered, it offers advanced features that can enhance productivity.

In summary, both performance and user experience are key. The best tool for you will depend on your specific needs and skills.

Frequently Asked Questions

What Is 2d Adaptive Clearing?

2D adaptive clearing is a machining strategy used in CNC milling. It optimizes tool paths for efficient material removal. This technique reduces machining time and tool wear. It ensures consistent load on the tool, improving overall efficiency.

Why Use Adaptive Clearing For Circular Patterns?

Adaptive clearing for circular patterns ensures smooth and efficient material removal. It minimizes tool engagement and reduces machining time. This technique enhances tool life and provides a consistent surface finish.

Which Tools Are Best For 2d Adaptive Clearing?

Carbide end mills are ideal for 2D adaptive clearing. They offer durability and precision. High-speed steel tools are also effective for this process.

How Does Adaptive Clearing Improve Efficiency?

Adaptive clearing improves efficiency by maintaining a constant tool load. It reduces tool wear and machining time. This results in faster and more precise machining processes.

Conclusion

Choosing the best tool for 2D adaptive clearing circular can be challenging. Focus on key features like efficiency, precision, and ease of use. Consider your project’s specific needs and budget. The right tool can save time and improve results. Research and compare options before deciding.

This ensures you get the best value and performance. Happy machining!